Regulatory changes have removed most commercial non-condensing pressure jet boilers from the market. However, those remaining, that can operate in condensing mode still represent a good option for certain commercial users. Charlie Mowbray, Commercial Product Manager, Ideal Heating

Regulatory changes have removed most commercial non-condensing pressure jet boilers from the market. However, those remaining, that can operate in condensing mode still represent a good option for certain commercial users. Charlie Mowbray, Commercial Product Manager, Ideal Heating

Boilers that operate with a pressure jet burner are common in industrial applications but over recent years have been largely removed from the domestic and commercial heating spheres.

Several regulatory changes have been responsible for this, including the Energy related Product (ErP) Directive which placed efficiency requirements on outputs under 400kW; the emission limit value requirements of the Medium Combustion Plant Directive (MCPD) for boilers with thermal inputs exceeding 1MW; and, most recently, the uplift to Building Regulations Part L which increased the Gross Seasonal Efficiency of natural gas boilers by two per cent in new buildings to 93 per cent for single boilers with less than 2MW output and to 88 per cent to those with more than 2MW. For oil boilers, the increase is even greater, going from 84 per cent to 93 per cent.

Compliance with Part L is required in new build and existing properties, including where comparatively large extensions are being built, where fixed building services are being modified or installed, or where there is an increase to the capacity of fixed building services.

These changes are necessary to reduce emissions and improve overall energy efficiency of the buildings and the systems within. Many pressure jet boilers designed to work in commercial applications have been unable to comply and have been withdrawn from the market. But not all. Those that can be operated in condensing mode are able to achieve the new, more demanding efficiencies and emission limits when matched to a suitable burner.

WHAT IS A CONDENSING PRESSURE JET BOILER?

The term “pressure jet” has become synonymous with large shell and tube boilers where a fanned burner with associated fuel controls is mounted to the combustion chamber. For a pressure jet boiler fuelled with gas this fuel is mixed with air that is blown through the burner by a fan, and ignited at the combustion head of the burner. Burner controls ensure proper fuel / air ratio and mixing across the range of operation, for efficient and complete combustion.

All commercial pressure jet burners used on gas or oil boilers work in this way, but only those that are fully able to operate in condensing mode are compliant.

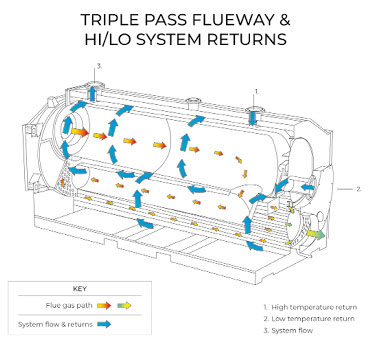

Condensing pressure jet boilers feature a double return condensing system (connections for high or low temperature return water) which enables them to keep the temperature difference between the heat exchanger wall and the return water high, thus maximising the formation of condensation.

WHY OPT FOR A CONDENSING PRESSURE JET BOILER?

In commercial settings, pressure jet boilers are rarely the first option to turn to as high-efficiency condensing boilers can achieve several megawatts. Plus, you have the option to cascade boilers.

The problem with this approach comes when plant room space is limited as cascades can, in some instances, take up quite a large floor area and present challenges installing all the flues and pipework to each boiler. This is where it is worth considering a condensing pressure jet boiler, which can deliver megawatts from a single unit of up to 3000kW.

Due to the high capacity of each individual pressure jet boiler, the system design and installation work for a pressure jet boiler can be considerably less complex in terms of the number of connections and the pipeline that needs to be put in, and the number of pieces of equipment you’ve got to deal with.

In the commercial sector, condensing pressure jet boilers are therefore most frequently suited to sites with large heating loads or where large capacity backup is required to support primary low/zero carbon heat sources. These typically include leisure facilities, hotels, healthcare facilities and the increasingly popular heat networks.

IMPORTANT CONSIDERATIONS

Condensing pressure jet boilers need to be considered carefully as they are not the ‘easy’ option when it comes to commercial heating.

Firstly, specialist installers and commissioning engineers are required who have the appropriate training for this type of equipment. The people who operate and maintain them also need suitable training, especially on the health and safety aspects such as Pressure Systems Safety Regulations; these are far more complex than your typical commercial boiler.

A robust water treatment and ongoing maintenance regime is essential to ensure safe and reliable operation. Inadequate water treatment will result in scale and corrosion, reducing the efficiency of the installation and potentially reducing the working life. Furthermore, the condition of the water supply used to initially fill the system can directly impact the quality of the overall heating system, if the water treatment is not correct.

REVALUATE YOUR OPTIONS

If your site has a high demand for heating and hot water, don’t exclude pressure jet boilers from your considerations. Those that operate in condensing could well provide you with an efficient solution that meets regulatory requirements

In association with https://idealcommercialboilers.com