Eur Ing Prof David Cooper MBE, CIBSE Vice President and CEO of independent lift and escalator consulting engineers LECS UK, looks at the causes of runaway escalators and questions whether current standards are sufficient

Eur Ing Prof David Cooper MBE, CIBSE Vice President and CEO of independent lift and escalator consulting engineers LECS UK, looks at the causes of runaway escalators and questions whether current standards are sufficient

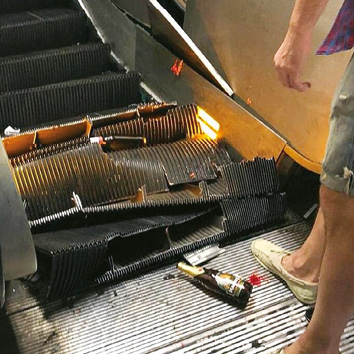

A runaway situation can occur when the escalator is running in ascent and descent modes, ultimately causing the escalator to roll backwards uncontrollably. In the up direction, this is known as a runback or unintended reversal; in down mode, it’s an uncontrolled descent starting from the rated speed of the escalator and increasing. Passengers often pile up at the bottom due to the high speed involved and sometimes clamber over the handrail to avoid collisions. This can lead to a fall from height.

There have been several incidents of uncontrolled movement (i.e. rolling backwards out of control) of escalator step bands, such as:

- 1994 Camden Yards, USA (43 injured)

- 2014 Cutty Sark station, London

- 2017 Mong Kok shopping mall, Hong Kong (17 injured)

- 2018 Piazza Della Republica, Rome (24 injured)

- 2023 Argyle Street station, Glasgow (5 injured)

The high-speed that the escalator step band achieves means there is no method of arresting the situation.

HOW CAN IT HAPPEN?

Investigations into the causes of such accidents have revealed several causes of uncontrolled movement, including auxiliary brake failure, drive unit fixing failure rendering the drive chain, brake, and gearbox ineffective, and other less common reasons.

Research indicates that passenger behaviour is a minor factor in runaways, such as pressing an emergency stop button leading to a primary cause such as brake failure. During an accelerating runaway, passengers often continue to board the down-running escalator, unaware of the issue.

This leads us to considering the design and maintenance of the escalators. Including an auxiliary brake is a design consideration, although not all escalators need one according to the EN115 standard. The location of the operational brake is also crucial; if it’s inboard of the gearbox, it won’t provide protection in the event of an internal gearbox failure.

Maintenance is also key in escalator runaway situations, especially regarding brake failures due to lubrication getting onto braking surfaces, poor adjustment, or worn pads. This can happen if the brake is frequently used to stop the escalator daily, causing regular wear.

Maintenance is also key in escalator runaway situations, especially regarding brake failures due to lubrication getting onto braking surfaces, poor adjustment, or worn pads. This can happen if the brake is frequently used to stop the escalator daily, causing regular wear.

CCTV of an incident in Rome shows the escalator slowing then speeding up, suggesting an emergency stop button was pressed but the operational brake failed to hold, causing a downward acceleration and passenger crushing. In my opinion, an auxiliary brake should be a device to prevent step band (the part that carries passengers up or down the escalator) runaway. For sound design, it must operate on the final mechanical component, likely to be the head shaft, to protect against failures.

ARE STANDARDS SUFFICIENT?

The 2017 EN115 standard (5.4.2.2) almost mirrors the 2008 and 1995 standard regarding the requirement for an auxiliary brake. It states:

5.4.2.2.1 Escalators and inclined moving walkways shall be equipped with auxiliary brake(s) if:

- a) The connection between the operational brake and the driving sprockets of the steps/pallets or the drum of the belt is not accomplished by shafts, gear wheels, multiplex chains, or more than one single chain, or

- b) The operational brake has not an electrical-mechanical brake according to 5.4.2.1.2, or

- c) The rise exceeds 6 m

The problem is that an escalator/inclined walk with a rise of less than 6 m can still fail and runaway due to brake failure, gearbox failure or drive chain failure. This is because the main drive chain is a vital part of an escalator’s power transmission system so when it breaks, the escalator loses its connection to the brake and drive device, and the steps can become uncontrollable.

CIBSE Guide D defines an auxiliary brake as: A fail safe brake… used to stop an escalator under all normal conditions or under certain fault conditions only. It is typically situated on one side of the main drive shaft.

The 2017 EN115 standard also calls for detection of unintentional reversal of the direction of travel and states: A device shall be provided for escalators and inclined (α = ≥6°) moving walks to detect the unintentional reversal of direction of travel.

The problem with this is that it could use the operational or auxiliary brake, if fitted, to prevent the reversal and these components are known to have failed in the past. 5.12.2.7.2 also calls for the detection of excessive speed before the speed exceeds a value of 1.2 times the nominal speed.

Perhaps the standards provide sufficient protection, however I contend that an auxiliary brake should be on all escalators/ inclined walks.

In addition, the auxiliary brake needs to be located in a position where compliance with 5.12.2.7.2 can be achieved. It is clear that the intent of the standard is to prevent uncontrolled movement of the step band and yet several escalator designs do not meet this requirement.

CONCLUSION

Runaway escalators still occur despite the EN115 standard acknowledging them as foreseeable events. Auxiliary brakes may not always offer full protection. Nonetheless, I suggest that all escalators and moving walks should be equipped with an auxiliary brake, properly positioned to prevent uncontrolled movement.

In association with www.lecsuk.co.uk