Tim Duret, Director of Sustainable Technology, Veolia on using advanced technology to deliver the circular economy

Tim Duret, Director of Sustainable Technology, Veolia on using advanced technology to deliver the circular economy

Advanced technology and process innovation is now transforming the recycling sector, providing a vital contribution to save the planet’s resources and move towards a circular economy.

According to government statistics – commercial and industrial waste amounts to 37 million tonnes per year, with over two-thirds generated by the commercial sector. Capturing the waste that is not currently recycled has the real potential of avoiding millions of tonnes of carbon emissions compared to extracting and processing virgin resources with carbon savings typically 50-85 per cent or more depending on the material.

Good recycling is about pushing the boundaries, and our successes so far give an indication of what can be achieved in the future. Backing this is the recycling industry’s ambition and willingness to invest in new infrastructure that can make this happen on an industrial scale.

What can be recycled spans a diverse range, from everyday items such as packaging, to solvents, paints, vapes, EV batteries, North Sea rigs and even the Wembley Stadium scoreboard.

TECHNOLOGY SOLUTIONS

Advancements such as Artificial Intelligence (AI) and machine learning are now part of Veolia’s GreenUp strategy. These use the forces of technology to reduce waste, enabling businesses to track the end-to-end impact of their operations throughout the value chain and contribute to meeting sustainability targets.

Waste collection is now set to gain from AI, we are trialing the digital scanning of waste and recycling entering collection vehicles to reduce contamination by utilising unique data and detailed flow analysis in real time.

Supporting this is the growth of equipment such as solar auto-compacting bins, which send notifications to collection crews when full, guided by route optimisation systems which will enable more waste to be collected more efficiently.

ENERGY SAVING AND COMPLIANCE

Electrified mobile plant and vehicles, supported by a charging network, will further change collections. Equipping vehicles with on-board weighing equipment to digitally record bin weights at premises boost performance and hand-held devices can provide on-the-go reporting by using digital tracking to monitor and auto-allocate tasks dependent on geographical location and capacity.

With a focus on air quality, electrified mobile plant and vehicles now operating across the waste handling process allow an 89 per cent reduction of CO2e emissions compared to a traditional diesel-powered fleet.

Ensuring compliance and traceability for hazardous and non-hazardous wastes is essential for businesses as non-compliance can bring the real risks of environmental impact and legal and financial penalties. By using the first end-to-end cloud-based system for complex wastes the complete cycle from enquiry through to collection, treatment and disposal can be effectively managed across more than 100,000 different waste streams. This enables customers to access waste management services quickly and generates all the necessary data to ensure correct classification, storage, off-site transportation, treatment and disposal.

AFTER COLLECTION

The next stage of the recycling operation is also gaining the benefit of technologies that can identify, sort and process materials.

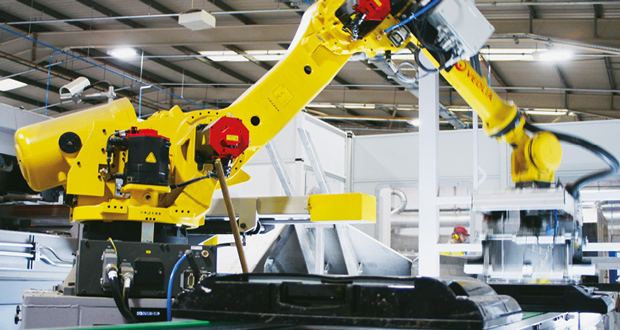

At Veolia’s Southwark Integrated Waste Management Facility an AI backed robotic arm, that’s as accurate as the human eye, is being used to pick out paper, card, mixed plastics and beverage cartons containing some aluminium layers, leaving just pure aluminium items for effective recycling. This streamlines the aluminium picking process, removing contamination from the final recyclate.

LCD screens using versions of the robots originally used on the assembly line, return the metals, including gold, silver, palladium, copper, and other valuable materials back to manufacturing processes.

Plastic recycling processes can now treat over 100 different grades of plastic and greater automation can be achieved by doing things as simple as changing the pigment in black plastic packaging. Even precious metals such as platinum can be extracted from pharmaceuticals which are past their use-by date, and liquid solvents can be recovered and transformed into new industrial products and secondary liquid fuels used in the manufacture of cement.

Sustainability isn’t just environmental. It has real long term economic and societal benefits as we strive to reach net zero targets. By developing and using advances in technology materials once thought of as non-recyclable can be retrieved and used in new applications. To take the next step forward, organisations need to see what is possible on their site and turn these ideas into a sustainable recycling reality. Only by doing this can we achieve the goal of a circular economy, and a sustainable future for our planet.