As waste disposal costs increase, Lee Knott, the Chief Executive of biotechnology business Advetec explains the benefits of turning non-recyclable waste into Solid Recovered Fuel (SRF)

As waste disposal costs increase, Lee Knott, the Chief Executive of biotechnology business Advetec explains the benefits of turning non-recyclable waste into Solid Recovered Fuel (SRF)

Faced with the onerous responsibility of Scope 3 emissions reporting and an ever-increasing need for the highest levels of environmental governance, facility managers must become more knowledgeable about the waste their organisations and supply chains create.

This is particularly timely as the waste industry is facing seismic change. The increase in Landfill Tax, as set out in the Spring Budget, is just one of the latest moves to drive more responsible waste practices. It’s coupled with more change on the horizon, too, including the decision to halve the amount of residual waste sent to landfill or incineration by 2042 and news that Energy from Waste (EfW) incineration will incur carbon emissions penalties from 2028 as it becomes part of the Emissions Trading Scheme (ETS).

These changes mean that traditional waste disposal will become much more expensive. For facilities teams striving to lower costs and improve their green credentials, measures such as scrutinising supply chains, encouraging greater recycling and moving to green energy will not suffice; they’ll also need to push for more innovative and cost-effective solutions from their waste handlers.

While some of these deadlines may seem far off, they don’t leave much time to navigate the sector’s significant changes. In 2026, EfW costs will likely rise to subsidise necessary technological changes, so the sooner facilities professionals and their waste partners investigate alternatives, the better the chance of a smooth and cost-effective transition.

COSTS WILL GO UP, NOT DOWN

As the Chief Executive of biotechnology business Advetec, which turns non-recyclable waste into Solid Recovered Fuel (SRF) I believe all of these changes are meant to make old waste habits undesirable and to drive positive change. The upshot is that sending waste to landfill or incineration will get much more expensive for waste handlers. Very few will be able to absorb these costs, so they’ll be passed on to customers and eat into FMs’ budgets.

The 20 per cent increase in Landfill Tax will make landfill a costly form of disposal, and it’s intended to push people more to incineration. But they’ll be caught with cost increases there too, as the Emissions Trading Scheme will see EfW operators taxed in relation to their carbon emissions. In turn, this will increase the cost of EfW for customers.

Under the ETS rules, which will affect EfW from 2028, the price per tonne is expected to be close to £170. That will comprise £100 for disposal and £70 tax.

The ETS is intended to combat climate change and reduce greenhouse gas emissions cost-effectively, and it’s already in use across Europe. It’s likely that the cost of landfill will increase even further in the UK to ensure that EfW, even with the hefty price hikes from ETS, is the more affordable and, therefore, used disposal route. Tax on carbon emissions is here to stay.

However, EfW isn’t the only option. More work is needed to educate organisations and FMs about the potential of their waste and, crucially, that alternative, more innovative, and financially favourable disposal routes already exist. Cost increases don’t have to be inevitable. The real opportunity is for the facilities community to exert their power and demand more innovative solutions from their waste handlers.

EMBRACE INNOVATION

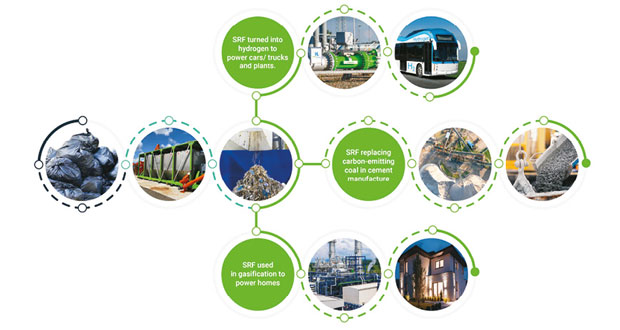

Solutions such as Advetec’s biotechnology divert 100 per cent of non-recyclable waste previously destined for landfill or incineration and turn it into SRF, which also opens up other offtake routes. It can be used as a coal replacement product to help heavy industries decarbonise, like cement manufacture. It’s also well suited for other uses, such as gasification, further segregation and recycling, and conversion into hydrogen to power cars and plants

As large-scale industries like cement production seek to decarbonise, demand for fuels like SRF increases. This is because SRF has a high proportion of biogenic carbon—which is not subject to the Emissions Trading Scheme.

Historically, smaller waste handlers have not pursued SRF creation as they’ve struggled to achieve the volumes, consistency and quality of waste required to meet SRF off-taker’s’ rigorous standards. Others simply did not know that SRF offtake was an option. Consequently, many facilities professionals have had little knowledge of it too.

Thankfully, the discussion around the waste is reaching fever pitch, and there’s a strong appetite for change. The UK’s landfill assets are almost at capacity, and the cost of EfW is rising, so there’s a growing acceptance that we must embrace other methods. More recycling is certainly part of that picture, but increasing the investment and infrastructure required will take time. One of the quickest ways to drive positive change now and lower costs and carbon is by turning non-recyclable waste into a commodity such as SRF.

As waste operators try to make sense of new legislation and rising costs, FMs can expect to share some of that pain, unless they set about investing in their waste knowledge. The more they know about the waste they create and the potential of those streams, the more they can demand of their waste partners and reap the benefits of reduced carbon and costs.